- #HACCP PROCESS 3 COMPLEX FOOD PREP HOW TO#

- #HACCP PROCESS 3 COMPLEX FOOD PREP VERIFICATION#

- #HACCP PROCESS 3 COMPLEX FOOD PREP DOWNLOAD#

Initial steps in developing an FSP include identifying all on-site food-related areas, drawing up a diagram or flowchart that covers all the food handling processes in each area and verifying the accuracy of this information on the production floor.

For example, a sushi station will require completely different food safety protocols than that of a bakery or hot food section. Keep in mind that separate HACCPs will be required for every product or food preparation station.

Before creating a food safety plan, appoint a committed management team familiar with the products and processes, who understand food safety principles, and who can take corrective action fast.

#HACCP PROCESS 3 COMPLEX FOOD PREP HOW TO#

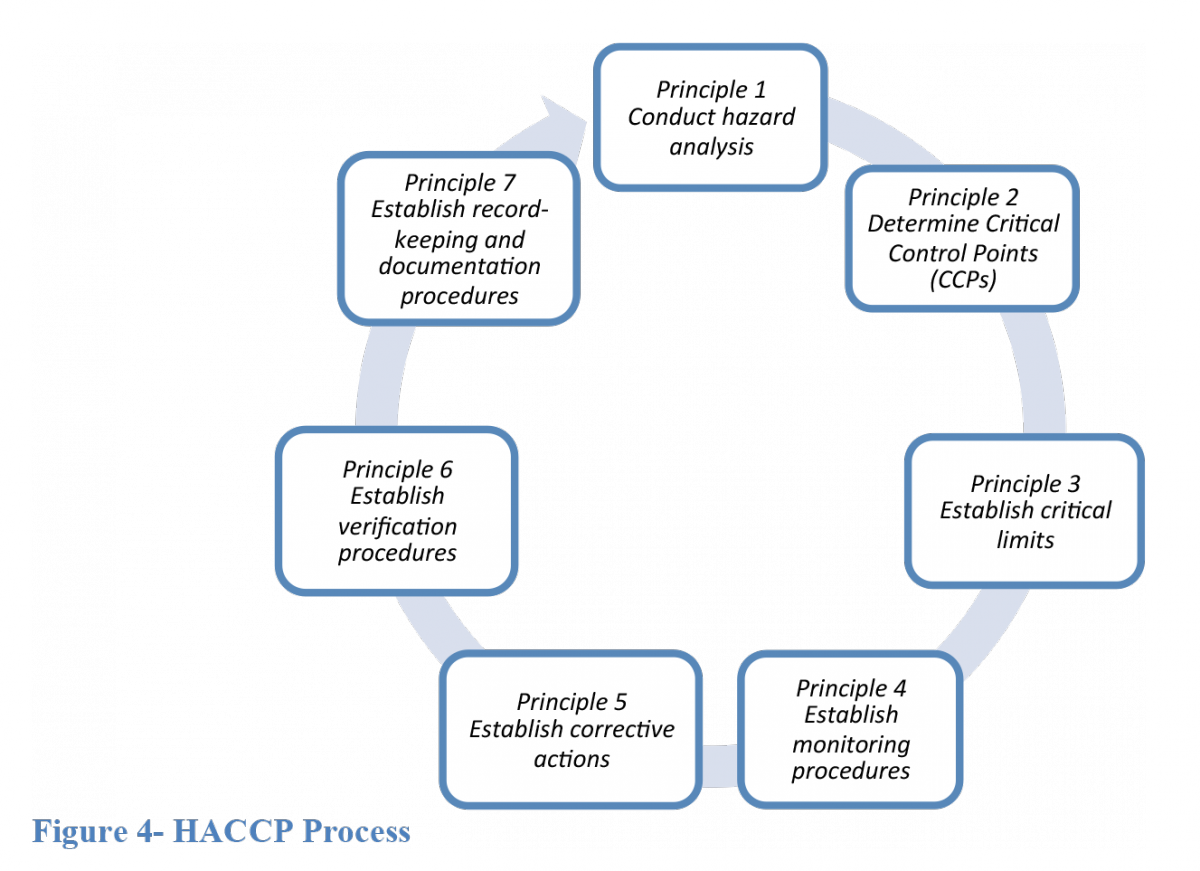

How to Create a Food Safety Plan Based on HACCPįrom raw material production to consumption of the finished product, HACCP implements science-based analysis and controls to ensure food safety. Lastly, every document also needs a prescribed recall plan for emergency situations.

#HACCP PROCESS 3 COMPLEX FOOD PREP VERIFICATION#

There also has to be a predetermined recording procedure and corrective action for when controls are not efficiently executed.Įach FSP document should include verification of proper implementation and should be validated by evidence that preventive controls are legitimate. There needs to be a monitoring system in place to ensure strategies are being implemented effectively. It ensures food safety responsibility is applied to every stage-specific food handler.Įvery food safety plan must include a hazard analysis for all food processes and a preventive control implementation strategy, including but not limited to process controls, sanitization, and allergen controls. This allows efficient oversight in food safety compliance laws on an ongoing basis and reduces the risk of unsafe products. Thorough record-keeping by each business is compulsory. In addition, it is imperative for businesses to keep records of all incidents and procedure implementations (in short, everything) as proof of having an effective FSP in place. Plans must be updated whenever operational changes occur or at a minimum of 3-year intervals. Each operator in the food lifecycle will have a different set of food safety protocols for their FSP according to applicable hazards at the specific stage, although there will be many overlapping safety measures.īy law, FSPs must be developed by an internal or external Preventive Controls Qualified Individual (PQCI). Īn FSP meticulously describes activities and tasks that safeguard food, from the initial stages of manufacturing and production through transportation, processing, and holding. It is a requirement under FDA regulation. What Is a Food Safety Plan?Ī food safety plan (FSP) outlines a systematic approach to the identification of food safety hazards that must be controlled to prevent or minimize the likelihood of foodborne illness.

#HACCP PROCESS 3 COMPLEX FOOD PREP DOWNLOAD#

Download The Operator’s Guide to Food Safety Execution for a walk through each critical step of executing strong food safety practices in all of your stores. Here is how digitizing your food safety processes can simplify your approach while improving the quality of your food safety measures. Food safety plans should not overlook staff training, sanitization and personal hygiene, pest control, and waste disposal, but should integrate these important functions into the plan at every stage. One guaranteed way to strengthen food safety standards is to implement a Food Safety Plan. Consumers who feel confident in the safety of your food products will undoubtedly choose your business over others. According to Food Safety News, consumer trust in the industry’s ability to meet food safety expectations is fairly low. Whether cooking and serving complex recipes in-house or simply heating and packaging prepared items to-go, employees are the last line of defense between customers and foodborne illness, especially during the food preparation process. Your staff is responsible for ensuring that every meal prepared at your establishment is a safe meal.

0 kommentar(er)

0 kommentar(er)